Sublet Tipple, 1907.

In addition to Diamondville, there were a number of other coal camps in the Diamondville-Kemmerer area. Nearby Oakley was named after

Thomas Sneddon's birthplace in Scotland. The Oakley mine closed in 1942. Glencoe, established in 1902, was named by

Sneddon after Glencoe, Scotland. By 1940, Glencoe was deserted. A similar fate met other coal camps in the

Diamondville-Kemmerer area. The original Elkol Mine (the Elk Coal Co.), established in 1908 south of

Diamondville, closed in 1950 but was replaced by an open pit mine now operated by

the Pittsburg & Midway Coal Mining Company.

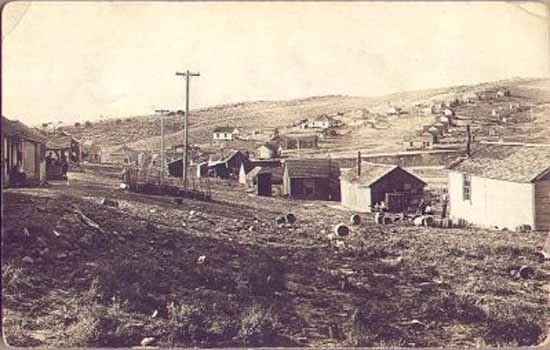

Sublet, Wyoming, 1908

Sublet and the nearby coal camp of Sublet No. 6 lay to the north of Kemmerer near or

adjacent to Willow Creek and along the Oyster Ridge Hogback. The Sublet mines were operated by the

Kemmerer Coal Company which in 1897 established its first mine at Frontier, a company town just to the

north of Kemmerer. Mine No. 3 was opened in 1901. In 1908 the company opened Mine No. 4 at Susie and No. 5 both in

the Willow Creek Valley. By 1913 The Company opened Sublet No. 6.

Ruins of Sublet No. 6 Sublet, 1993 Oyster Ridge, looking east from the west side of Willow Creek.

The upper building is the remains of the hoist house. To its right is a boiler. Below the hoist house is

the engine house. The engine house originally housed a steam engine which provided power for electtical generators for the hoist house

and the mine. To the left of the engine house is the remains of another boiler. The darker area leading down to a concrete wall are

the remains of the tipple. At the bottom right in the photo is a tailing area. The steam engine would have fallen into

disuse in 1918 when two 500 K.W. generators powered by steam turbines were installed at

Frontier. From there 2300 volt line served Sublet No. 6 and No. 5. With the availablity of greater power,

electric locomotives replaced horses in the mine itself.

Remains of Sublet No. 6 Tipple.

A trestle crossing the railroad and the creek connected the tipple to the No. 2 Portal. The tipple was originally a corrigated metal structure. Steel cables connected to the hoist pulled cars

up the trestle to the tipple.

Portal No. 2, west side of Willow Creek.

Entry to the mine was through Portal No. 1 further to the south. Initially, horses brought the cars out of the mine to

the pictured portal. Gravity would power the cars down the trestle to the mine. Going down slope, the cars were slowed by the

use of "McGinty" blocks or props in which the steel cables were wound against the props so that friction of the cables against

the blocks would slow down the cars. It, like all work in the mine, was dangerous. Thus, as an

example one miner caught both hands in the ropes and literally had the fingers of his hands pulled off, leaving

him with only his thumbs. As a result of the injuries, he could no longer feed or dress himself. See

Sakamoto v. Kemmerer Coal Co., 36 Wyo. 325, 259 P. 356 (1927).

Remains of Fan House, Sublet No. 6 Mine.

The fan house housed a ten foot Stevens fan which provided

ventilation for the entire mine. The fan could provide in excess of 65,000 cubic feet of air per

minute.

The miners used black powder to blast the coal. Each miner had a can in which the powder was kept. At the end of

a shift, a miner would take his can to the powder house where it would be refilled for the next day.

To mine the coal, a charge of powder would be set on the face. The charge would be connected to a fuse which

would be lit. The miner would then retreat and await the sound of the explosion. After the

explosion was heard, the miner would return to the face. Sometimes coal in the ceiling would have

been loosened but not fall. Later,l after the miner had returned, the coal would fall. A number of miners were called in

this fashion. Others were killed when they mistook the sound of another miner's charge for their own. When

they returned, their own charge would then go off. On July 26, 1920, eight miners awaiting to have their

powder cans refilled at the powder house were killed when the powder house blew up. It was suspected that the

cause of the explosion was a spark when a new keg of powder was being opened.

Remains of a house.

Both Sublet and Sublet No. 6 were Company towns. Thus, the housing was provided by the Company.

Remains of house. Beyond are the ruins of the hoist house and

engine house. Across the valley is Portal No. 2.

Following World War I, demand for coal was reduced and operation of the mine became seasonal. In

1925 and 1926 coal prices increased and production increased. In the first five months of 1927, the

mine was in operation only 54 days. The last coal was produced in May of that year. A new mine, Gomer, named after the

manager of Sublet No. 6, Gomer Reese, replaced Sublet No. 6.

Fires in underground mines are always a danger.

In Diamondville, there was a Christmasday fire in 1898. Another fire occurred in

in October 1901, when 22 were killed, and another in 1905 killed 18. At the nearby

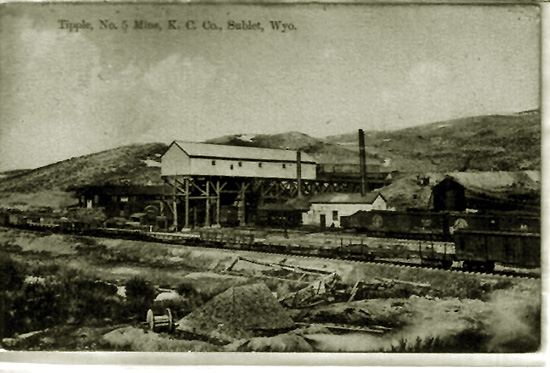

Sublet No. 5 a mine explosion on September 16, 1924, killed 39 miners.

Sublet Tipple No. 5, undated.

The Sublet No. 6 mine

closed in 1927. And as discussed on subsequent pages, one by one, the various coal camps

across the state closed as the era of underground mining ended to be replaced by open pit or

strip mining.

Next Page: Cumberland.

|