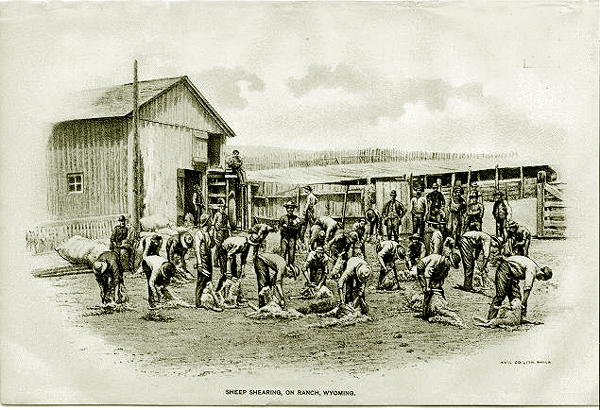

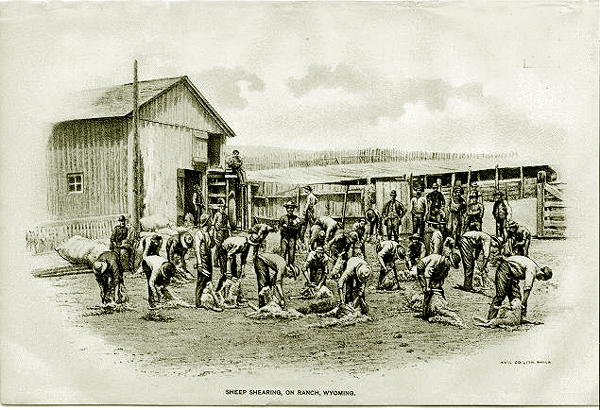

Sheep Shearing on a Wyoming ranch, 1892.

The Sheep industry in Wyoming was primarily the production of wool. At first, shearing was done on the open ground.

Bands of shearers would move from ranch to ranch at shearing time. Shearing time was immediately on either side of Lambing Season, usually beginning in

April or May. The shearing was done in the open as depicted above.

Begining about 1895 steam, electrically and gasoline powered mechanical

shearing plants or sheds were introduced.

King Brothers Shearing Shed, east of Laramie.

Maude Radford Warren described the process of shearing in a commercial pen:

. The owner of the pen we patronized charged us fifteen

cents a head to shear our sheep. He supplied shed, corrals, shearers, men

to handle the sheep, and bags for the wool. The shearing shed was long,

with open sides flanked by numerous little pens. Into each pen a man, called a

wrangler, drove a certain number of sheep. The shearer dragged one

out, sat it on its liaunches, clasped it with his knees and free hand

and began to cut away the fleece at the point of the shoulder. Some

of the shears and clippers are run by steam or electric power. I liked

better the hand-clipping, which seems to ofl'er more safety to the sheep.

In from two to five minutes—the longer it took the less the animal

suffered from cuts—the fleece rolled to the floor. The shearer tied it

in a bundle, tossed it out of his way and passed the shorn animal to

another wrangler, who put on its backor side the owner's brand in

black paint.

The packers, pushing and trampling down the wool, put the fleeces into

long burlap sacks, which when full weighed from two hundred and fifty

to three hundred pounds, unwashed. I was surprised to find that, though

the average weight of a fleece is nine pounds “in the grease," yet the

shrinkage after washing is perhaps sixty-eight per cent. On the range,

every hard wind blows sand and grit. into the fleece and the natural

grease holds it all fast. Wool brings twenty or twenty-one cents a pound.

"A Woman Piorneer With the Sheep," Saturday Evening Post, May 13, 1910, p. 8

The packers referred to by Mrs. Warren were also referred to as "trompers"

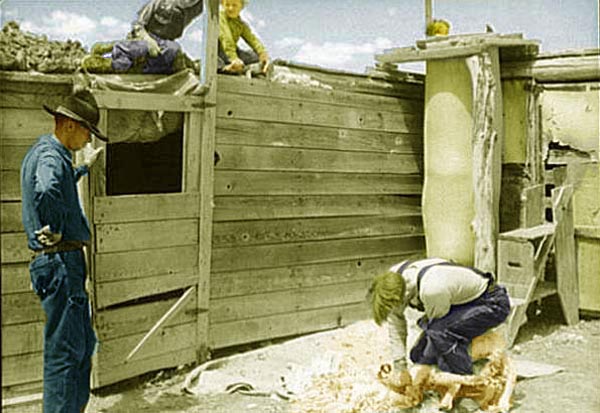

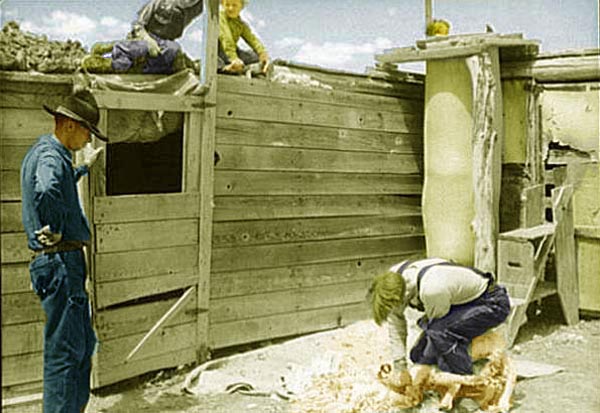

Sheep Shearing, undated.

The platform behind the shearers is the wool tromper's platform.

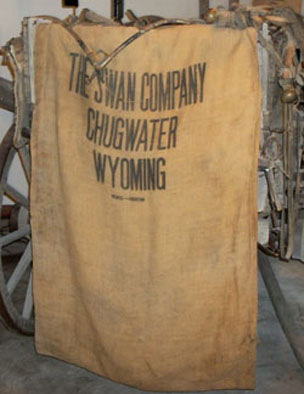

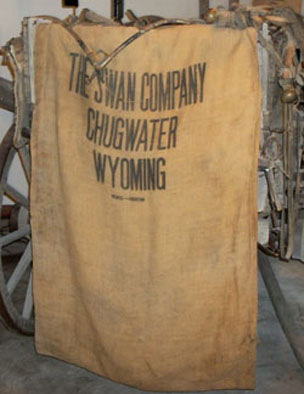

Left: Swan wool sack, portion of display in

museum in Chugwater, Photo by Geoff Dobson, 2013.

Right, Wool "Tromper," 1939, courtesy Library of Congress

Wool sacks were generally about eight feet long. In the Middle Ages the weight of the wool in a wool sack was fixed at 26 stones (364 pounds).

During the rein of Edward III, a bale of wool was placed in the Lords' chamber at Westminster as the seat of the Lord Chancellor. The Kingdom's

wealth at the time was dependent upon the production of wool.Thus the bale became the symbol of the

prosperity of the realm. Gradually the bale, known as the "Woolsack," became more ornate, upholstered in crimson with tassels on

each corner. In 1938, it was refilled with wool from Australia, New Zealand and South Africa.

Periodically members of the House have debated the

condition of the Woolsack as the seat became depressed perhaps from the weighty matters argued before the House as well as

the weight of of the

respective speakers. It is now the seat of the

Speaker of the House of Lords. Currently it is filled with wool from those Commonwealth countries who commercially export wool.

The Woolsack has become a symbol of

the prosperity of the Commonwealth and its unity. Although wool is important to Wyoming, the presiding officer of the Wyoming Senate presides from a rather

mundane seat, not nearly as magnificent as a bale of wool. [Writer's note: Perhaps the President of the Senate's chair could be replaced

during the current (2016) renovations of the Capitol with a bale of alfafa suitably

upholstered to remind the members that it is a house of the people.]

Swan wool sacks awaiting shipment, undated.

To fill the sacks with wool, a sack would be suspended from a

metal ring supported by the platform. After each sheep is sheared, the fleece would be tied into a ball by the

shearer ang tossed into the sack in which a "wool tromper" would be standing. It was his job to pack the wool

down into the sack with his feet working from the outside of the sack. He would gradually work is way up. When the

sack was full, it would be sewn shut with twine and a large needle.

"Tromping wool," .

Today each sack holda 500 to 800 pounds of wool. While bending over and

shearing the sheep might be hard on the back. Tromping the wool was dirty. At the end of the day, the wool tromper would have to

pick off ticks that he had accumulated.

With the decline in demand for wool, the steam powered and electrically powered

sheep shearing sheds have fairly well disappeared. For the most part, however, the process of shearing, except for the introduction of

electrically powered shears, has remained fairly the same with the shearer holding the sheep between his legs.

Compare the next two photos.

Sheep Shearing, Converse County, 1939.

In the corner is the platform for tromping the wool with the wool tromper's head barely visible above the edge.

The size of the sack can be determined from the photo.

A tarpoleon has been placed on the ground. Clean wool without brings more.

Sheep Shearing, New Zealand, 2013. Photo by Geoff Dobson..

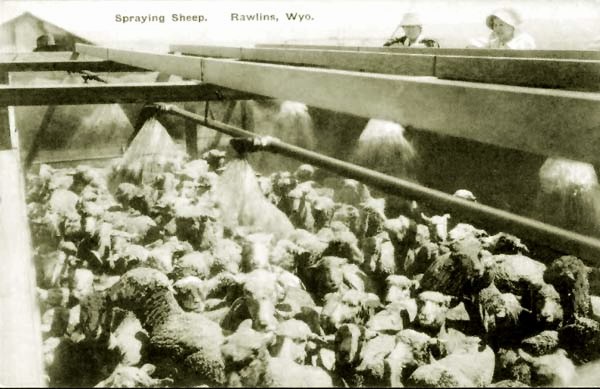

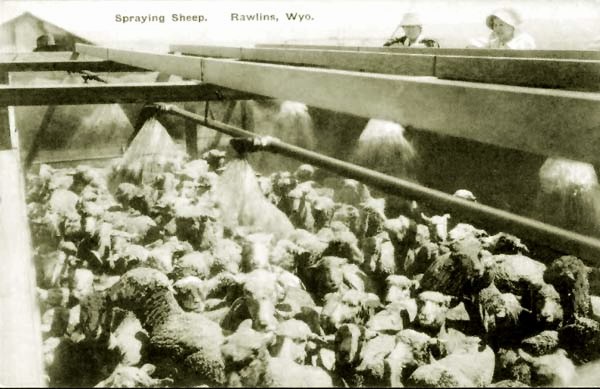

When shearing was done, came the job of sheep dipping, spraying and marking.

Sheep Spraying, Rawlins, undated.

The purpose of sheep dipping and spraying was to eliminate scabies and ticks. It was mandated by Wyoming law. For complete

discussion of the subject, see State v. Hall, 27 Wyo. 224, 194 Pac 476 (1920), upholding the constitionality of mandatory sheep dippping.

Marking Lambs near Douglas, undated

The marking and counting of the young lambs was done before the lambs and ewes were returned to

summer range.

Just as branding of cattle dates back to ancient Egypt, the practice of

marking sheep goes back into antiquity. The ordinances of the Isle of Man provided in 1510, as an

example:

" The forester or his deputy ought to go forth on St. Collum Eve through

the forest, and ride to the highest hill-top in the Isle of Man, and there

blow his horn thrice; this done, to range and view the forest, and on the

third day to go forth and take such company with him as he shall like, to

see what sheep he findeth unshorn. If he finde any, he ought to take them

with his dogge, if the said sheep be not milk sheep, to shear them and to

take the fleece to himself and to put a private mark upon said sheep, to

use all he finds within the precincts of the forest so at the time, to the

intent that if any of the said sheep be found the next year by the same

iforester, he to certify the comptroller and receiver of the same, that

they may be recorded in the Court Rolls and so priced and sold to the

Lord's best profit, etc."

[Writer's note: St. Collum Eve, St. Columba's Eve, June 9.] Originally marking of sheep was done by ear

marks or ear clipping. Today,

it is done with colored markers with a choice of bright colors, sometimes

in an aerosol can.

But the decline of the wool and lamb industries has not been limited to the United States. The New Zealand sheep shearer in the depicted above told the

writer that he receives for his wool less than a third that his father also a sheepman received. He now pulls in a few extra pence by demonstrating his sheep dogs and

giving demonstrations of sheep shearing on his North Island sheep station.

His father recieved one pound (£1) for a pound of wool. At the time of the Korean War there was a large demand

for wool. Synthetics and the end of subsidies by the New Zealand Government were responsible for the decline in pricing.

The emphasis is now on meat productions. On a visit to Iceland,

the writer received the same story. Icelander meat exports are nil. Wool production is now primarily for domestic use. By 2005 there were only

three knitting mills left on the Island. That year in an effort to help the wool industry, a new knitting mill, Víkurprjón which collaborated with Vík Prjónsdóttir,

a design shop, was opened at the village of Vík í Mýrda, on a small bay on the south coast of Iceland.

Unfortunately in 2012, the mill was sold and moved elsewhere on the island.

Music this Page: "Click Go the Shears," as sung by Burl Ives.

Next Page, Wool Trains

|